Documentation Requirements for Record-Keeping in Manufacturing: A Practical Guide to GMP Compliance

When you're making medicine, medical devices, or even food in a factory, the paperwork isn't just busywork-it's what keeps people safe. If a batch of pills is contaminated or a medical device fails because someone skipped a step, the blame doesn't land on a machine. It lands on the documentation. That’s why record-keeping in manufacturing isn’t optional. It’s the law. And it’s the difference between a recall that costs millions and a product that saves lives.

Why Documentation Matters More Than You Think

In 2022, a single missing temperature log led to a $15 million product recall. That’s not a hypothetical. It happened. A warehouse shipment of insulin wasn’t monitored properly during transit, and no one wrote it down. When the product reached patients, some doses were ineffective. The FDA didn’t fine the company for poor storage-they fined them for not documenting the failure. Good Manufacturing Practices (GMP) were born from tragedy. After 107 people died in 1937 from a toxic drug solvent, the U.S. government realized: you can’t just rely on people to do the right thing. You need proof they did it. That’s where documentation comes in. Today, GMP rules are enforced globally by the FDA, the European Union, and over 50 other regulators. And they all agree on one thing: if it wasn’t written down, it didn’t happen.What Counts as a Record?

Not every note or email is a record. In manufacturing, records are official, controlled documents that prove a process was done correctly. There are two main types:- Procedural documents: These are your instructions. Standard Operating Procedures (SOPs), test methods, equipment cleaning guides, and bills of materials. They tell people exactly what to do, step by step.

- Compliance records: These are the proof. Signed batch records, lab test results, environmental monitoring logs, equipment maintenance logs. These show that the SOPs were followed.

The ALCOA+ Rules: The Non-Negotiables

Your records must follow ALCOA+. It’s not a suggestion. It’s a requirement. Here’s what each letter means:- A - Attributable: Every entry must have a name, date, and time. No anonymous notes.

- L - Legible: Handwritten entries must be clear. Typed entries must be readable. No smudges, faded ink, or unclear scans.

- C - Contemporaneous: You write it down as you do it. Not the next day. Not at the end of the shift. Right then. The FDA allows up to 24 hours for electronic entries, but paper records must be signed within minutes of the action.

- O - Original: Use the first data point. Don’t copy from a sticky note into a logbook. Don’t retype raw instrument data unless the original is preserved.

- A - Accurate: No guessing. No "approximately." If a temperature reads 24.7°C, write 24.7°C. Not "about 25."

- + - Complete, Consistent, Enduring, Available: Every field filled. No contradictions. Data lasts the full retention period. And anyone who needs it-auditors, regulators, inspectors-can access it.

Electronic vs. Paper: What’s Required Today?

Paper records still exist, but they’re fading fast. Most manufacturers now use electronic quality management systems (eQMS). But here’s the catch: electronic records aren’t easier-they’re more complex. If you use software to log data, you need:- System validation (GAMP 5 guidelines) to prove the software works correctly

- Electronic signatures that meet 21 CFR Part 11 (identity verification + audit trail)

- Audit trails that log every change-who made it, when, and why

- Backups that last longer than your product’s shelf life

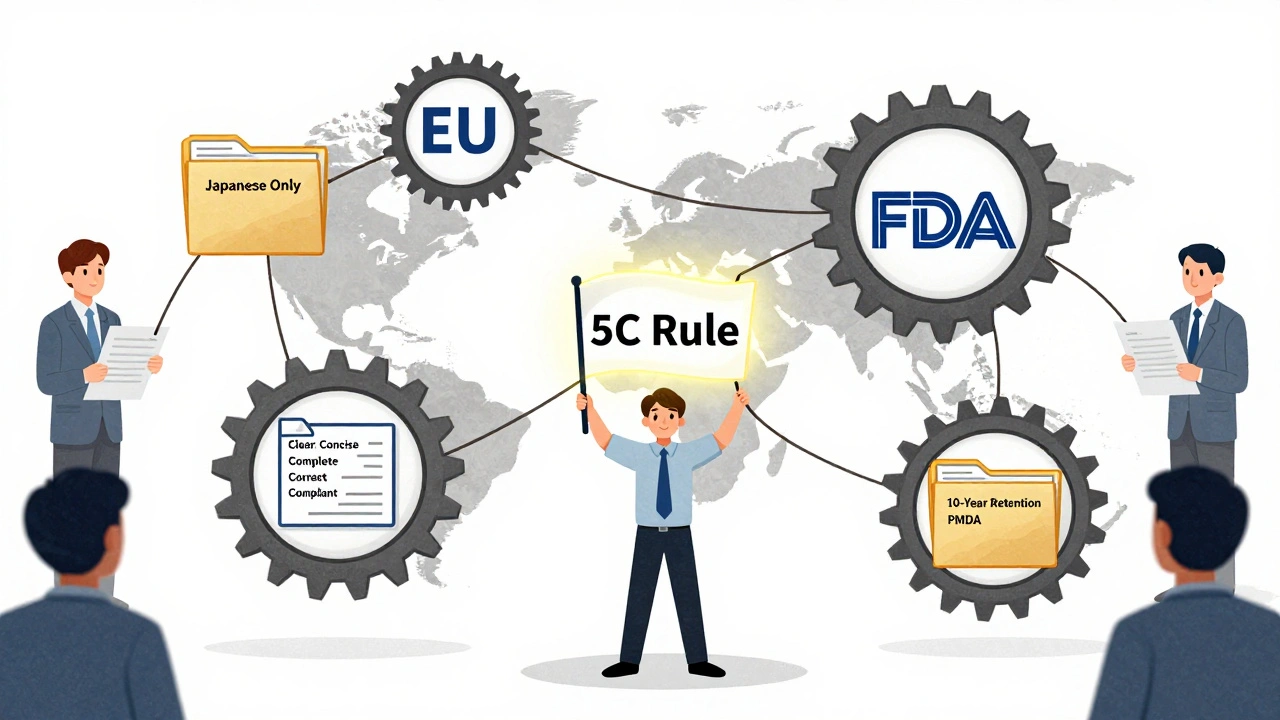

Regional Differences You Can’t Ignore

Just because you follow the FDA doesn’t mean you’re compliant in Europe or Japan.- U.S. FDA (21 CFR Part 211): Requires a second person to verify all calculations. No shortcuts.

- EU GMP (EudraLex Volume 4): Allows automated verification systems. No need for manual double-checks if the system is validated.

- Japan (PMDA): All documents submitted locally must be in Japanese-even if your company is based in Canada.

- Medical devices: ISO 13485 demands traceability from design specs to final test results. FDA doesn’t require that level of linkage.

What Gets You in Trouble

The FDA’s 2021 analysis of warning letters shows the top three documentation failures:- Incomplete batch records (32%): Missing timestamps, skipped steps, unsigned sections.

- Inadequate investigations (27%): "Something went wrong" without root cause, corrective actions, or proof it won’t happen again.

- Untimely record completion (21%): Waiting until the end of the week to fill out logs.

How to Get It Right

You don’t need a team of lawyers to build a compliant system. You need a few smart habits:- Write SOPs at an 8th-grade reading level. If a new hire can’t understand it, they won’t follow it.

- Use the "four-eyes" rule. Critical records (like batch releases) need two people to review and sign.

- Appoint documentation champions in each department. Someone who knows the rules and answers questions before audits.

- Follow the 5C rule: Clear, Concise, Complete, Correct, Compliant. If it doesn’t meet all five, scrap it.

The Future of Documentation

AI is starting to help. Some companies are using systems that auto-generate batch records from machine data. MIT found early adopters cut documentation time by 45%. But regulators aren’t ready yet. The FDA hasn’t approved AI-generated records without human review. For now, AI is a helper-not a replacement. By January 2025, the EU will require risk-based documentation. That means you must document why you’re keeping certain records-and why you’re not keeping others. No more blanket rules. You’ll need to justify every page. The bottom line? Documentation isn’t slowing you down. It’s protecting you. And in manufacturing, protection isn’t a cost. It’s your license to operate.What happens if I don’t follow GMP documentation rules?

Non-compliance can lead to FDA Form 483 observations, warning letters, product recalls, or even facility shutdowns. In 2022, the average recall cost manufacturers $10 million. Some companies lose their license to operate entirely. Beyond financial loss, damaged reputation and loss of customer trust can be irreversible.

Can I use handwritten records in 2025?

Yes, but it’s risky. Handwritten records must meet ALCOA+ standards: legible, signed, dated, and stored securely. Most manufacturers now use electronic systems because they reduce errors, automate audit trails, and make inspections faster. If you still use paper, you need strict controls to prevent loss, tampering, or illegibility.

How long do I need to keep manufacturing records?

Regulations vary. In the U.S., records must be kept for at least one year beyond the product’s expiration date. In the EU, they must be kept for at least three years after the product is distributed. For medical devices, retention can extend to 10 years under MDR 2017/745. Always check the specific rule for your product type and market.

Do I need to validate my electronic documentation system?

Yes. If you use software to create, store, or manage records, it must be validated under GAMP 5 guidelines. This means proving the system works as intended, secures data, has audit trails, and prevents unauthorized changes. Validation isn’t a one-time task-it’s ongoing. Updates, patches, and upgrades require re-validation.

What’s the most common mistake in manufacturing documentation?

Waiting to write things down. People think they’ll remember the details and fill it in later. They don’t. That’s why 42% of FDA observations are for untimely records. The best rule: if you did it, document it-right then. No exceptions.

Is documentation really the biggest issue in manufacturing compliance?

Yes. According to Dr. Markus Gershon, former FDA Senior Compliance Officer, 87% of FDA warning letters in 2021 were due to data integrity failures-mostly documentation. Regulators now spend 30% more time reviewing documentation than facility conditions during audits. Your factory might be spotless, but if your records are messy, you’re still in violation.

Man, I used to think paperwork was just a hassle until my buddy’s plant got shut down over a missing signature. Now I get it-no doc, no product. Simple as that.

soooo many ppl think docs are for auditors but honestly its for the person next shift who has no clue what happened and needs to fix it before the whole batch goes sideways 😅

Monica’s right-documentation isn’t about impressing regulators. It’s about keeping your team from making the same mistake twice. I’ve seen new hires save entire runs just because they checked the logbook. That’s power.

I’ve always found it fascinating how something so mundane-like writing down a temperature-can carry the weight of human lives. It’s not bureaucracy; it’s a moral contract. We write because we care, even when no one’s watching.

And yet… we still treat it like a chore. Why? Because we’ve forgotten the why. Not the regulation, not the fine, but the mother who needs her insulin to work. The child who needs the ventilator to breathe. The silence between the lines is where the humanity lives.

When I was training new techs, I’d say: ‘Don’t sign your name because you’re told to. Sign it because someone, somewhere, is counting on you to be the reason they didn’t die today.’

It’s not ALCOA+. It’s ALCOA+ with heart.

And yes, I know I over-punctuate. But if you’re gonna change the world, you might as well do it with commas.

Bro… I just saw a guy write ‘~25C’ on a log. 😳 I nearly cried. We’re making LIFE-SAVING drugs, not guessing game scores!!

Also-why is no one talking about how AI is gonna change this? I’m not saying let bots sign stuff… but if my machine auto-logs temp, humidity, and pressure… why am I typing it again? 🤔

Let me tell you about the time our QA lead found a batch record with a pen that had run out of ink… and someone tried to trace over it with a highlighter. 🤯

The auditor didn’t even speak. He just stared. And then he closed his notebook. And walked out.

That plant? Shut down for six months. Six. Months.

People… we’re not just filling out forms. We’re writing the last line of defense between a patient and disaster.

Oh please. You think this is hard? Try doing this in India where half the workers can’t read English and the pens dry up in 30 seconds. We’re not in Silicon Valley. This ‘ALCOA+’ nonsense is a luxury for rich countries.

At least in the US you have fancy computers. Here? We write on napkins and pray.

Wait-so if I use a stylus on a tablet and it auto-signs with my fingerprint… is that still ‘original’? Or does the ‘original’ have to be the raw sensor data before the app formats it? And if the system auto-populates the time zone… is that contemporaneous if I’m in EST but the server’s in UTC?

I’m not being pedantic. I’m trying to survive the next audit.

Neelam, I hear you. But let’s not confuse resource constraints with compliance. Even in low-resource settings, you can use simple, low-tech solutions-pre-printed logs, color-coded pens, buddy checks. The goal isn’t perfection-it’s integrity. And integrity is possible anywhere.

Just because something’s hard doesn’t mean it’s impossible. And the cost of getting it wrong? Far higher than the effort to get it right.

Ha! You Americans think you invented compliance? In India, we’ve been documenting for centuries-on palm leaves, in temple ledgers, with ink made from soot and honey. Your ‘ALCOA+’? We had ‘ALCOA+’ before your ancestors were farming wheat.

And don’t get me started on your ‘eQMS’-you think your software is secure? My cousin hacked a FDA audit system last year using a USB stick he bought at a bazaar. You’re all just playing dress-up with compliance.

Have you ever wondered… what if the FDA is using this as a cover? What if they don’t actually care about patient safety? What if they’re using documentation requirements to control the industry? To force small manufacturers out? To create a monopoly for Big Pharma? I’ve seen the documents. They’re not just checking records-they’re hunting for excuses to shut you down.

And what about the ‘audit trail’? Who’s auditing the auditors? 😈

Look, I get it. Docs are important. But come on. We’re not launching rockets here. Just write it down, sign it, move on. Stop overthinking it.